Call us now

metal frame lcd and touch screen full lamination

Price 1.0 USD ($)/ Piece

metal frame lcd and touch screen full lamination Specification

- Output

- HD visual output

- Operating Temperature

- -20C to 70C

- Input

- Capacitive touch

- Power Source

- External DC

- Usage

- Industrial, commercial, educational, and consumer electronics

- IP Rating

- IP54

- Power Supply

- USB/Adapter

- Display Type

- IPS LCD with full lamination

- Interface

- HDMI, USB, I2C for touch

- Sensors Specification

- Built-in capacitive touch sensor

- Thermal Conductivity

- Standard

- Resolution

- 1024 x 600 pixels

- Components

- LCD display, capacitive touch panel, metal frame

- Response Time

- 5 ms

- Features

- Anti-glare, scratch-resistant, wide viewing angle, high brightness

- Product Type

- Metal Frame LCD and Touch Screen (Full Lamination)

- Application

- Kiosks, digital signage, POS, ATM, tablets

- Rated Voltage

- 5V DC

- Supply Voltage

- 5V

- Size

- 7 inch

- Dimension (L*W*H)

- 165mm x 100mm x 7mm

- Function

- Touch input and visual display

- Color

- Black

- Weight

- Approx. 250g

- Thickness

- 7mm

- Current Rating

- 1A

- Capacity

- Multi-touch (10 points)

- Frequency

- 60 Hz

- Surface Treatment

- Anti-fingerprint coating

- Storage Temperature

- -30°C to 80°C

- Touch Technology

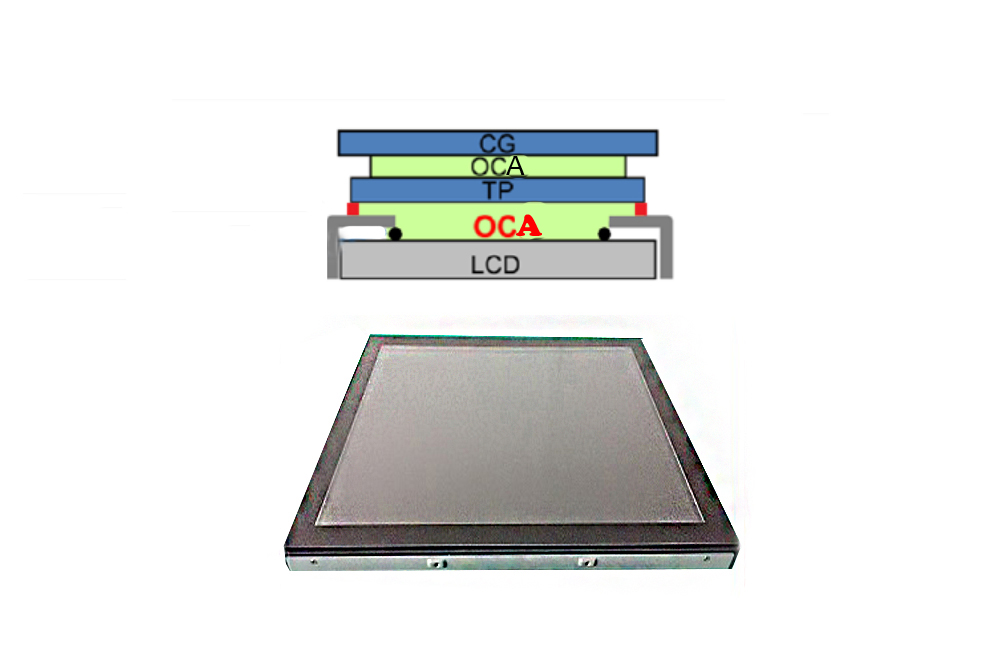

- G+G full lamination

- Cover Glass Hardness

- 6H

- Contrast Ratio

- 800:1

- Mounting Type

- Panel mount / VESA mount compatible

- Frame Material

- Aluminum alloy

- Viewing Angle

- 178° (H) / 178° (V)

- Operating Humidity

- 10% - 90% RH, non-condensing

- Backlight Life

- > 30,000 hours

metal frame lcd and touch screen full lamination Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- SHENZHEN

- Payment Terms

- Paypal, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 25 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Vacuum-formed tray packaging Carton Wooden

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East

- Main Domestic Market

- All India

- Certifications

- CE ROHS

About metal frame lcd and touch screen full lamination

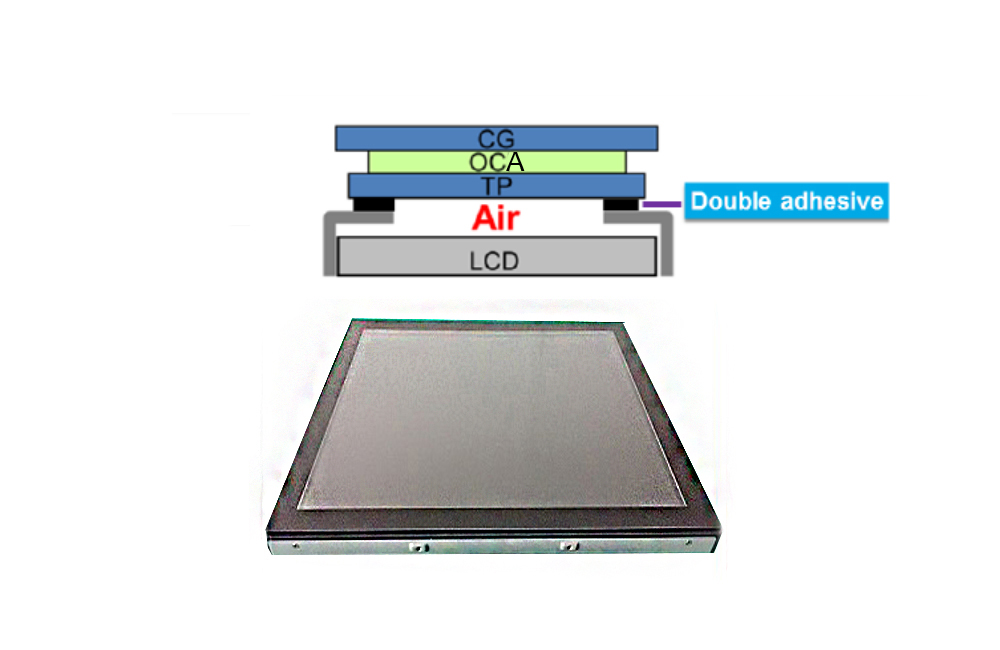

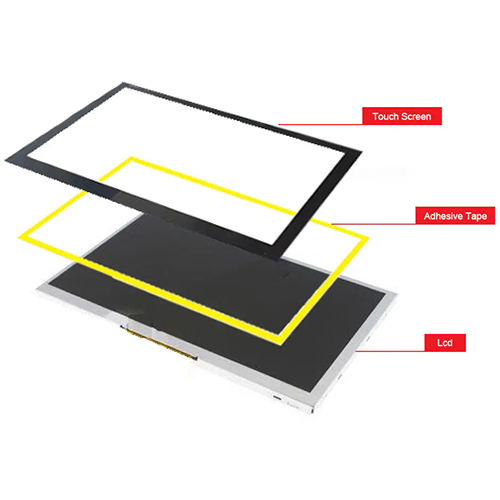

Frame/BezelBonding

It is a traditional method, bond the touch screen to the LCD frameby 3M adhesive tape or foam adhesive tape. There is air gap between the touch and LCD.

Suitable for the general consumer electronics, cheap cost application products, small sizes solutions.

1. Make frame bonding TOOLS

2. Bond in DUST-FREE workshop

3. Strict QUALITY control

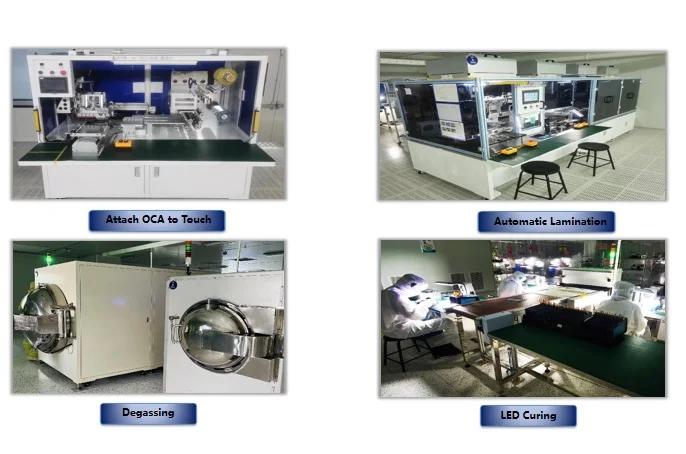

FullLamination-OCA

1.Surface PretreatmentClean the surfaces of the touch screen and LCD to remove dust, oil, and impurities.

2.OCA Lamination (for Small to Medium-Sized Displays)Precisely attach the OCA adhesive film onto the touch screen using a vacuum laminator. Then bond the touch screen to the LCD.

3.Vacuum Thermal PressingCure the OCA adhesive completely through thermal pressing under vacuum, then degassing.

4.UV Curing & Quality InspectionDo UV curing andoptical inspection to verify lamination quality (e.g., bubble count, alignment accuracy, and transmittance).

Full Lamination -FLOCA (Fill Liquid Optical Clear Adhesive)

We developed a full lamination solution by FLOCA, which have advantages in the full lamination between capacitive touch screen and LCD module, especially big size LCD with metal frame , or capacitive touch screen with curved or abnormal shapes.

Wide Viewing Experience

With a 178 horizontal and vertical viewing angle, this IPS LCD touch screen delivers consistent, vibrant colors from almost any direction. Its HD resolution (1024x600 pixels) ensures clarity whether used in kiosks, tablets, POS systems, or signage. The anti-glare, anti-fingerprint coating maintains visibility and cleanliness during prolonged use.

Durable Metal Frame and Screen

Engineered from aluminum alloy, the metal frame offers lightweight strength with a stylish aesthetic. The 6H hard glass surface is scratch-resistant for reliability in high-traffic setups. The full lamination G+G touch technology not only enhances visual sharpness but also increases touch accuracy and durability-meeting the demands of commercial environments.

Flexible Mounting and Connectivity

Easily integrate this touch display with various mounting options including panel mount and VESA compatibility. It supports multiple interfaces-HDMI for video input, and USB/I2C for touch functionality-making installation straightforward for industrial, educational, or consumer setups. Power it conveniently via 5V DC using either an adapter or USB connection.

FAQ's of metal frame lcd and touch screen full lamination:

Q: How does full lamination technology benefit this LCD touch screen?

A: Full lamination (G+G) eliminates the air gap between the glass and LCD, resulting in sharper images, reduced reflection, higher touch accuracy, and improved durability compared to standard non-laminated displays.Q: What environments can this metal frame LCD be used in?

A: It is designed for various applications such as industrial automation, digital kiosks, POS terminals, educational equipment, ATMs, and consumer electronics, thanks to its IP54 rating, wide temperature tolerance, and anti-scratch coating.Q: What is the process for mounting this LCD touch screen?

A: The display supports both panel and VESA mount types, allowing flexible installation on walls, enclosures, or stands. Simply align the mounting holes to your bracket and secure it with compatible screws.Q: What power supply options are available for this screen?

A: The unit operates on 5V DC and can be powered using a USB port or an external adapter, providing versatility for different deployment scenarios.Q: When should I consider this screen for my project?

A: This screen is suitable when you require reliable, high-resolution touch interaction in demanding or public settings, with the benefits of a sturdy aluminum frame, multi-touch support, anti-fingerprint coating, and a long backlight lifespan of over 30,000 hours.Q: Where can this product be exported or supplied from?

A: This LCD touch screen is manufactured, supplied, and exported from China, making it accessible for international industrial, commercial, and educational applications.Q: What are the benefits of the anti-fingerprint and scratch-resistant surface?

A: The 6H hardness and anti-fingerprint coatings ensure the surface resists scratches and smudges, maintaining a clear and professional look even with frequent touch interactions in high-traffic environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Optical Bonding Service( TOUCH+DISPLAY) Category

LCD and touch screen with optical lamination by OCA

Price 1.0 USD ($) / Piece

Minimum Order Quantity : 10 Pieces

Color : Black (frame), Transparent (display area)

Application : Industrial, Medical, Commercial, Consumer Electronics

Size : 7 inch (customizable)

Product Type : LCD Touch Screen with Optical Lamination

frame/bezel bonding between touch and lcd, cheap bonding

Price 1.0 USD ($) / Piece

Minimum Order Quantity : 10 Pieces

Color : Black

Application : Mobile phones, Tablets, Industrial Displays, Consumer Electronics

Size : Customized to screen frame size

Product Type : Bonding Adhesive or Doublesided Tape

LCD And Touch Screen Lamination, full lamination, oca lamination, touch lcd module

Price 1.0 USD ($) / Piece

Minimum Order Quantity : 10 Pieces

Color : Different Available

Application : Commercial

Size : Different Available

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry