Call us now

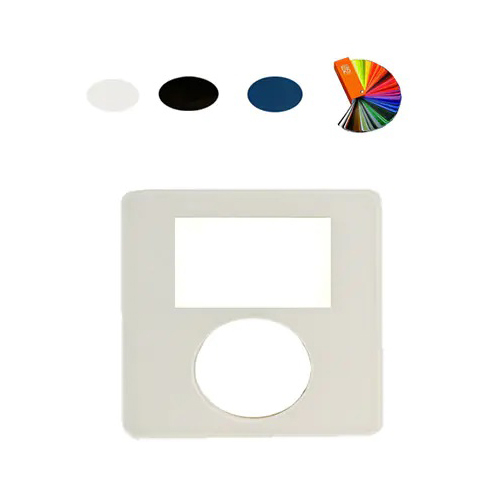

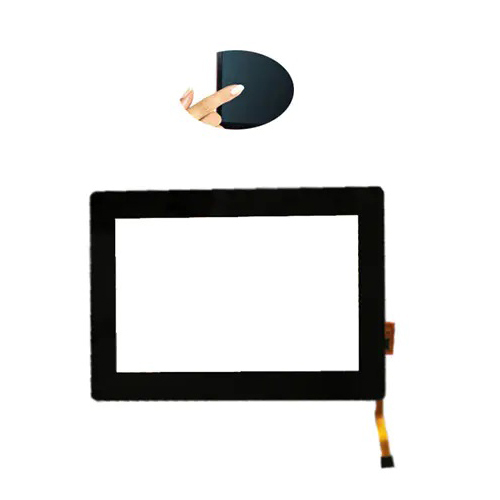

Different Color Cover Lens, multi touch screen, POS touch screen

Price 10.0 USD ($)/ Piece

Different Color Cover Lens, multi touch screen, POS touch screen Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- SHENZHEN

- Payment Terms

- Paypal, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 25 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Vacuum-formed tray packaging Carton Wooden

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East

- Main Domestic Market

- All India

- Certifications

- CE ROHS

About Different Color Cover Lens, multi touch screen, POS touch screen

1.Custom size capacitive touch screen

Factory pricing touch screen

Size from 1.54 inch to 65 inch capacitive touch screen

2.Capacitive touch screen structure GFF, GF, GG(SITO), GG(DITO), OGS

3.Cover lens materials:

Soda-lime glass or High-alumina glass

4.Cover lens Thickness:

0.55mm(suggest size < 6 inch

0.7mmsuggest size <10.1 inch

1.0mm(custom thickness

1.1/1.8mm( standard thickness)

2.0mmcustom thickness

3.0mm (Standard thickness)

4.0/5.0mmcustom thickness)

5. Cover Glass Surface Treatment:

a. AF: Anti-fingerprint

Commonly used processes include spraying and electroplating. Electroplating offers better friction resistance but is more expensive.

b. AR: Anti-reflection

Using an electroplating process, it appears purple, red, or blue, giving an overall high-end visual effect.

c. AG: Anti-glare

Commonly used processes include etching and spraying. The etching process provides better friction resistance.

6. Glass sensor

6.1 Thickness

0.4/0.55/0.7/1.1/1.8mm

6.2 Sheet Resistance

4060 / 6090 / 80120 / 200300 : Anti-Ghosting Treatment required.

300500 / 400600 :Anti-Ghosting Treatment optional (suitable for small to medium-sized displays only).

6.3 Strengthening Treatment

Standard: No additional treatment.

Chemical Strengthening:

Recommended for: Sensors with a thickness of 0.4 mm or Structures where the sensor directly contacts the housing.

7. Film Sensor

7.1 Thickness

0.05mm Easily prone to pressure damage and bending damage, only suitable for small sizes

0.075mm

0.1mm

0.125mm

7.2 Sheet Resistance

10050 : Poor etching marks, suitable for medium to large screens.

15050 : Industrially mature material, currently widely used.

8. OCA

8.1 Liquid OCA

Lower cost, but edge wet glue cannot be completely removed, and adhesive thickness uniformity is poor. It has been largely phased out.

8.2 Solid OCA

Higher cost, with uniform adhesive thickness, but not easy to rework during the manufacturing process. Used in some customized products long before for the unity.

8.3 UV-curable Solid OCA (SCA)

Higher cost, with uniform adhesive thickness and easy rework during the manufacturing process. Currently the mainstream material.

9. How to custom a touch screen?

Tell us:

A. Touch dimension, thickness, FPC postion etc

B. IC solution, interface

C. Cover lens thickness,color, printings, logo, special coating(AF,AG,AR)

D. Back adhesive tape thickness and brand

E. Touch points, origin(0,0) positon

F. Hardware platform, operation system etc.

G.MotherboardIC withpull-up resistors or not

10. Application of touch screen

A. Consumer Electronics(Smartphones & Tablets,Smartwatches & Wearables)

B.Retail & Hospitality(POS Systems,Self-Service Kiosks)

C.Automotive(Car Infotainment Systems,Dashboard Navigation)

D.Industrial & Manufacturing(Factory Automation,Medical Devices

E.Education & Public Sector(Study tablets, E-readers,Iteractive kiosks, Advertising machine)

F.Gaming & Entertainment(Arcade Machines,Casino & Lottery Terminals, Toys)

G.Home Automation & Smart Devices(Smart Home Control Panels,Voice-Activated Touch Devices)

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Customize Touch Screen Category

Water Resistance Capacitive Touch Screen

Price 10.0 USD ($) / Piece

Minimum Order Quantity : 10 Pieces

Color : Different Available

Service Period : 6 To 12 Months

Design : Modern

Application : Commercial

Capacitive Touch With Anti-Finger Treatment, custom touch sensor

Price 10.0 USD ($) / Piece

Minimum Order Quantity : 10 Pieces

Color : Different Available

Service Period : 6 To 12 Months

Design : Modern

Application : Commercial

Touch Screen With Different Color Printings, custom industrial capacitive touch screen, custom touch overlay, customize industrial touch panel

Price 10.0 USD ($) / Piece

Minimum Order Quantity : 100 Pieces

Color : Different Available

Service Period : 6 To 12 Months

Design : Modern

Application : Commercial

Anti-glare Treatment Capacitive Touch Screen, military grade touch screen

Price 10.0 USD ($) / Piece

Minimum Order Quantity : 10 Pieces

Color : Different Available

Service Period : 6 To 12 Months

Design : Modern

Application : Commercial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry