Call us now

1.4 inch 4 wire resistive touch screen

Price 0.5 USD ($)/ Piece

1.4 inch 4 wire resistive touch screen Specification

- Equipment Type

- Touch Sensor Input

- Weight

- Approx. 5g

- Dimension (L*W*H)

- Approx. 34.5mm x 41.9mm (Active Area)

- Application

- Portable Devices, Handheld Terminals, Industrial Equipment, Kiosks, Medical Devices

- Thickness

- 1.2mm (Typical)

- Standard

- RoHS Compliant

- Design

- Overlay, 4-Wire Configuration

- Output Voltage

- Varies with touch coordinate/external controller

- Color

- Transparent (Active Area), Black (Frame)

- Input Voltage

- DC 3V~5V

- Supply Voltage

- DC 5V (Typical)

- Finish

- Smooth, Matte Surface

- Tolerance

- 0.1mm

- Processing

- Precision Tail Cutting and Lamination

- Usage

- Input Interface

- Size

- 1.4 inch

- Material

- ITO Glass + PET Film

- Temperature

- Operating: -10C to +60C, Storage: -20C to +70C

- Humidity

- Up to 90% RH (non-condensing)

- Process

- Surface ITO Etching, Tail FPC Bonding

- IP Rating

- IP54 (front, if properly mounted)

- Service Period

- Up to 1 million touches or approx. 3~5 years

- Product Type

- 4 Wire Resistive Touch Screen

- Installation Guideline

- Integrate above LCD/TFT display panel using adhesive or frame

- Technique

- Resistive Layer Technology

- Mounting Type

- Adhesive or Mechanical Frame Mount

- Surface Treatment

- Anti-glare/Hard-coating (Customizable)

- Frequency

- DC Response (No Frequency)

- Linearity

- 1.5%

- Light Transmittance

- 80%

- Durability

- 1,000,000 touches at same spot

- Storage Temperature

- -20C to +70C

- Actuation Force

- 30~120g

- Insulation Resistance

- >20M at 25V DC

- Contact Resistance

- 100 ~ 800

- Response Time

- <10ms

- Interface

- Analog, to be paired with Touch Controller

- Connector Type

- FPC (Flexible Printed Circuit), 4 Pin

1.4 inch 4 wire resistive touch screen Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- shenzhen

- Payment Terms

- Paypal, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 25 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

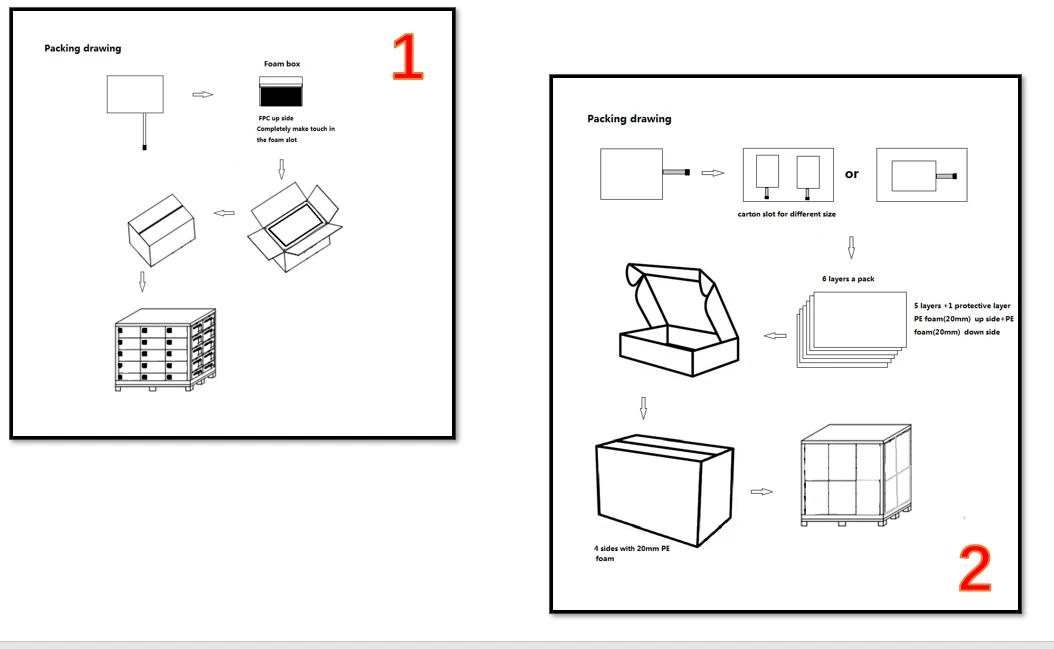

- Packaging Details

- PE foam tray packaging Carton Wooden

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe

- Main Domestic Market

- All India

- Certifications

- CE ROHS

About 1.4 inch 4 wire resistive touch screen

1.4 inch 4 wire resistive touch panel, accept customization

Intercom systems: Video door phone, video peephole viewer, phone etc.

Safety and Security: Monitors, touch PCs

Consumer Electrics: Advertising players, TVs, ATMs etc.

Telecommunication Devices: Telephone, Interphone, watch, radio, etc.

Home Appliances: Washing Machine, Refrigerator, Home Integrator ,digital photo frame

Industrial Control: Homoeostasis Numerically-controlled machine tool

Instrument and Apparatus: Tester, Medical instruments

Vehicle-mounted Digital: MP3, MP4 and vehicle-mounted air conditioner

Mining: Mine's lamp charger, gas tester

Marine: Salinity tester

Parameters:

| Size available | 1.4,1.8,2.0,2.4,2.8,3,3.2,3.5,3.8,4.3,4.5,4.8,5,5.6,6.5,7,7.5,8,8.4,10,10.1, 10.4,12.1,14,15,15.4,15.6,17,18.5,19,21.5,23.6 INCH | ||

| Performance | |||

| Resoslution | 4096*4096 | ||

| Linearity Error | <2.5% | ||

| Response Speed | <10ms | ||

| Mechanical | |||

| Input Method | Finger or stylus | ||

| Life Span | More than 10 million touches | ||

| Pressure | 10-100g | ||

| Surface Hardness | 3H | ||

| Optical | |||

| Light Transmission | >78% | ||

| Structure | |||

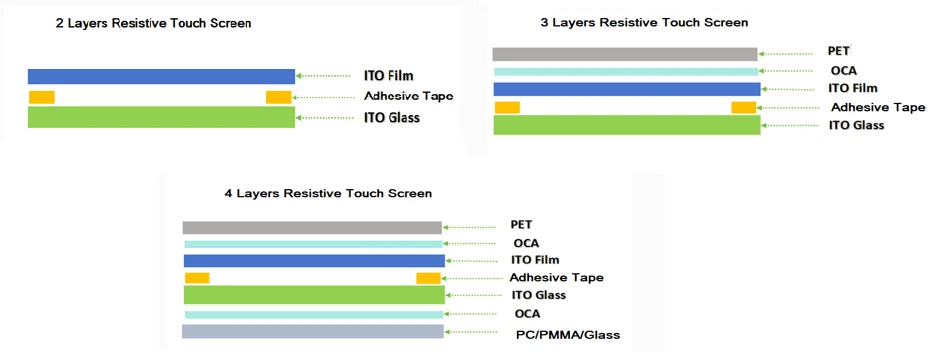

| 2 layers | Film+ITO glass | ||

| 3 layers | PET+Film+ITO glass (cusomize) | ||

| 4 layers | PET+Film+ITO glass+PC/PMMA/GLASS (customize) | ||

| Environmental | |||

| Operating Temperature | -10 50C | ||

| Storage Temperature | -20 60C | ||

| Operating Humidity | 0%90% | ||

| Storage Humidity | 0% to 95% | ||

| Electrical | |||

| Voltage | Typical 3-7V | ||

| Current | 5mA25mA | ||

| Interface | Full Duplex USB 2.0 (Full Speed) Plug and play compatible | ||

| Serial RS-232. Baud Rate: 9600, 8 Data Bits, 1 Stop Bit, No Parity | |||

| Isolation Resistance | >20M | ||

| Resistance | 300< X Axis <900, 200< Y Axis <800 (Varies with different size) | ||

| Agency Approvals | CE, Rohs | ||

| Operation System | Linux/ Dos / Windows /Mac/QNX | ||

| Standard controller | EETI 5 wire/4 wire USB/RS232 controller kits(include board and calbes) | ||

| Special requirements | High-Transmittance Glass,light touch, Strengthened Glass,optional | ||

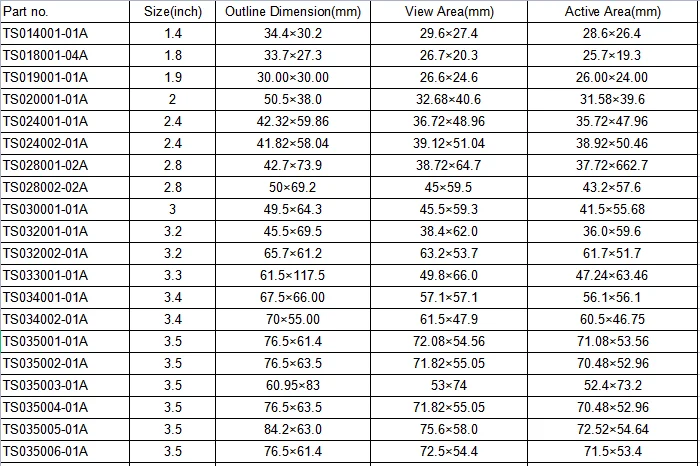

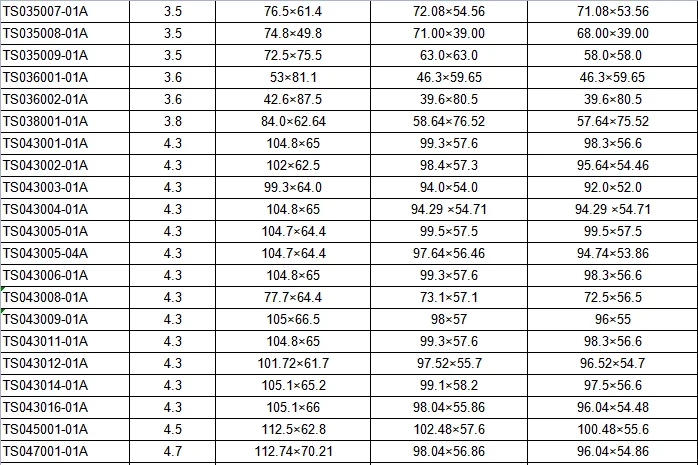

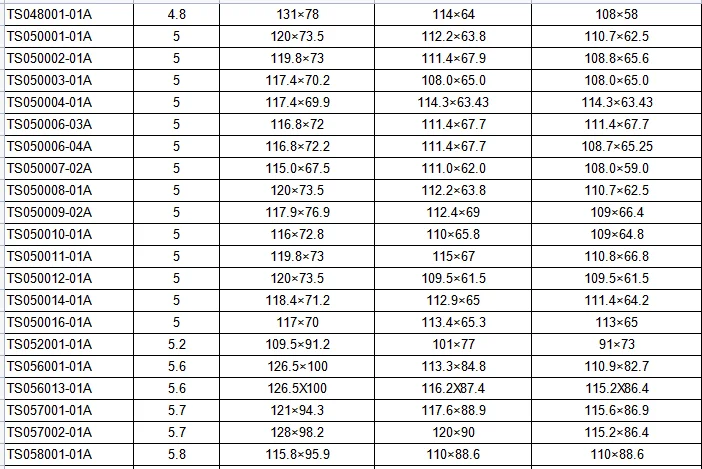

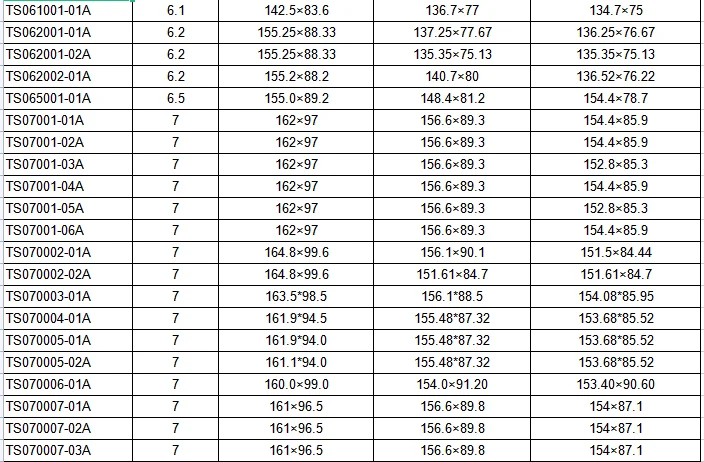

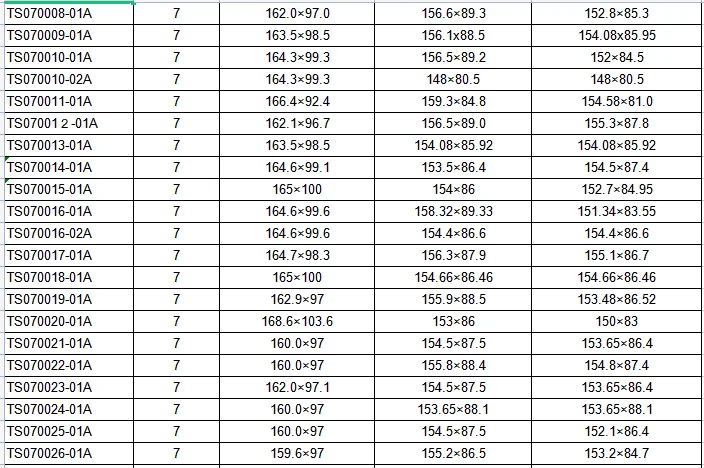

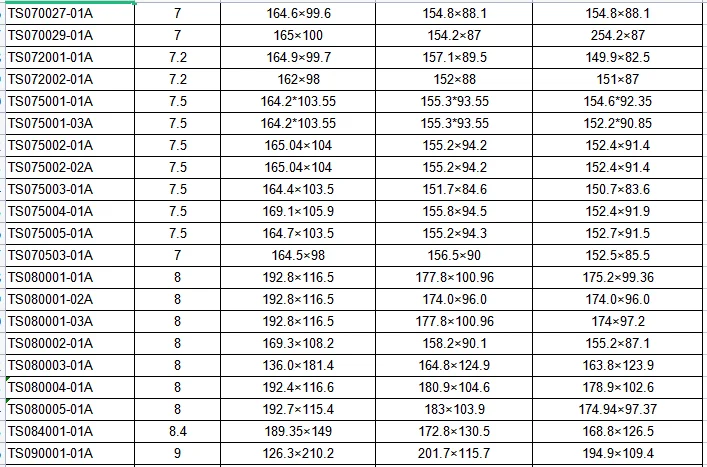

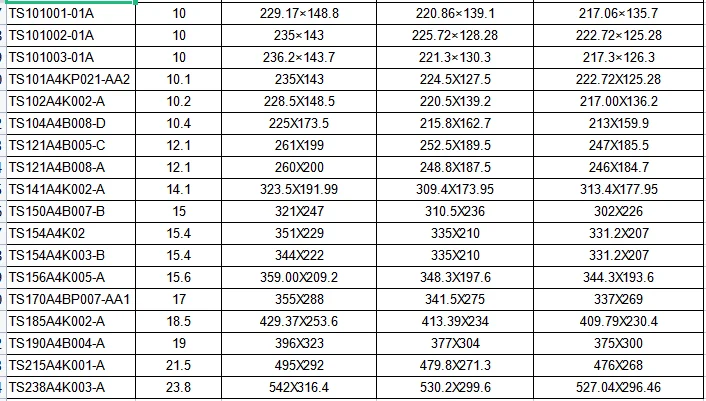

Available 4 wire resistive touch screen models:( if haven't found suitable one, please contact with us.)

Sturcture

ITO FILM

Classification by Surface Treatment

a. Glossy Anti-Scratch Surface Low haze, providing better visual clarity. More challenging manufacturing process. Lower durability against scratches.

b. Glossy Anti-Newton Ring Surface Includes an anti-Newton ring layer. Reduces manufacturing difficulty.

c. Matte Anti-Glare Surface Features an anti-glare layer. Optimized for outdoor use with improved visibility.

Classification by Sheet Resistance

a. Low Resistance Primarily used in digital resistive touchscreens. Lower loop resistance, resulting in higher sensitivity.

b. High Resistance Mainly used in analog resistive touchscreens. Lighter etching traces, offering better visual appearance.

Classification by ITO Film Substrate

a. Single-Layer Film Uses a single-layer PET substrate, lower cost.

b. Double-Layer Film Uses a dual-layer composite PET substrate, higher cost. Softer and more durable, used in high-end products.

ITO GLASS

Classification by Strength

a. Chemically Strengthened Glass Treated with chemical tempering to increase surface compressive stress. Enhances overall strength but at a higher cost.

b. Standard Glass Conventional glass without special strengthening treatment

Classification by Transmittance

a. High-Transmittance Glass (AR-Coated) Features anti-reflective (AR) coating, improving light transmission by 3% over standard glass.

b. Standard Glass No additional optical enhancement.

Classification by Thickness

Standard Thicknesses: 0.7mm / 1.1mm / 1.8mm

Special Thicknesses: 0.55mm / 2.8mm

Classification by Resistance

a. High Resistance (400) Used in analog resistive touchscreens.

b. Low Resistance Primarily for digital resistive touchscreens.

FPC

a. Core Materials of FPC: Base Material, Copper Foil, Stiffener, Coverlay

b. Common FPC Structures for Touchscreens

Touchscreens typically use either: Single-layer FPC/Double-layer FPC

c. FPC Material Specifications Base Material

Adhesive-based: Contains adhesive layer between copper and PI (polyimide).

Adhesive-less: Eliminates adhesive layer, consisting only of copper foil and PI (Thinner profile, Superior dimensional stability, Enhanced heat resistance, flex endurance, and chemical resistance, Now widely adopted in industry)

Copper Foil

Rolled Copper: Better flex endurance;Not suitable for ultra-thin boards or fine circuitry;Commonly used in resistive touch screens

Electrodeposited Copper: Preferred for capacitive touch screens

Stiffener Materials:

| Type | Characteristics | Application |

| PI | Low cost, prone to deformation | Resistive touchscreens |

| FR4 | Balanced cost/performance | Mid-range applications |

| Steel | High performance, expensive | Capacitive touchscreens |

PET COVER LENS

Thickness

| Thickness | Characteristics | Application |

| 0.125mm | Lighter touch force, poorer flatness | Niche applications requiring sensitive touch |

| 0.188mm | Balanced touch force and flatness | Standard for RTP (Resistive Touch Panels) |

| 0.25mm | Higher touch force, excellent flatness | Applications requiring durability |

Surface treatment

| Type | Characteristics | Key Parameters | Usage |

| Glossy Anti-Scratch | Scratch-resistant coating | High transmittance Low haze | Most common (indoor devices) |

| Matte Anti-Glare (AG) | Diffuse surface treatment | Reduced reflectivity Higher haze | Outdoor/sunlight-readable products |

| Glossy Anti-Newton Ring | Multi-layer optical construction | Eliminates Newton Ring | Limited use (3-layer" framed panels) |

Carrier Plate

Material

| Material | Characteristics |

| PC (Polycarbonate) | Impact-resistant, but lower surface hardness (max 2H), cost-effective |

| PMMA (Acrylic) | Impact-resistant, higher surface hardness (up to 3H), prone to warping/shrinkage |

| PC/PMMA Composite | Combines benefits of PC & PMMA, but higher cost |

| Glass | High surface hardness (6H), minimal warping/shrinkage, moderate cost, but less impact-resistant than plastics |

Thickness

Glass: 0.55mm / 0.7mm / 1.1mm / 1.8mm

PC/PMMA/Composite: 0.5mm / 0.65mm / 0.8mm / 1.0mm / 1.5mm

How to assemble the resistive touch screen to the housing?

To prevent false triggers, the housing must not directly contact the active touch area. Maintain an air gap of 0.20mm0.50mm between the housing and touchscreen surface. Recommendations for Customers: Step Design Add a peripheral step on the housing(Foam Tape) Width: Should not exceed TP silver trace boundaries Height: 0.20.5mm

When installing a resistive touch screen, it is recommended not to position the FPC downward. In outdoor environments with significant temperature differences, water vapor may condense on the touch screen surface. Additionally, external water, under the influence of gravity, may flow along the touch screen surface, seep through the casing, and reach the FPC bonding area. This can corrode the FPC bonding position and affect product reliability. If the touch screen is installed in this orientation, the waterproof performance of the entire device should be designed to a higher level.

Do resistive touchscreens require calibration?

A resistive touchscreen detects touch positions by measuring voltage signals generated at the contact point. When a finger or stylus presses the screen, the conductive layers (typically made of ITO) at the touched location undergo a change in resistance, producing corresponding voltage signals. These signals are then converted into X and Y coordinates, enabling precise touch recognition and positioning. From the operational principle described above, the key takeaway is that resistive touchscreens rely on voltage signal acquisition for coordinate recognition. The consistency of these voltage signals is fundamentally determined by the uniformity of the conductive layer (ITO layer). Industry-Specific Manufacturing Reality: ITO Layer Production: The industry-standard magnetron sputtering deposition process inherently creates thickness variations This results in sheet resistance (a conductivity equivalent) tolerances Typical industry specification: 400100 (representing 25% variance) Performance Implications: Inter-panel voltage distribution variations are unavoidable due to: Initial sheet resistance tolerances Thickness non-uniformity (typically 5% across panel) Long-Term Performance Factors: ITO layer degradation characteristics: Annual sheet resistance drift: 3-8% (accelerated by environmental factors) Operational lifespan impact: 50,000+ touch cycles (industry benchmark) Compensation Solution: Dynamic calibration protocols are implemented to: Compensate for initial manufacturing variances Counteract progressive ITO aging effects Maintain 1% coordinate accuracy throughout product lifecycle In summary, to ensure touch accuracy, calibration is essential for resistive touchscreens.

Package

Office

Factory

High Precision, Durable Design

With a linearity of 1.5% and insulation resistance above 20M at 25V DC, this resistive touch screen ensures accuracy and long-term stability. Its robust construction supports over 1 million touches at a single spot, making it perfect for high-usage devices in demanding settings.

Easy Integration and Versatile Mounting

Designed for seamless integration above LCD or TFT display panels, this touch screen can be installed using adhesive or a mechanical frame. Its FPC (Flexible Printed Circuit) connector with 4 pins and a typical supply voltage of DC 5V ensure compatibility with a wide range of touch controllers and host devices.

Reliable Performance Across Conditions

Engineered to withstand challenging environments, this touch sensor operates at temperatures from -10C to +60C and can be stored at -20C to +70C. The IP54 rating (front side) ensures resistance to dust and water splashes when properly mounted, while its anti-glare finish maintains visibility in various lighting conditions.

FAQ's of 1.4 inch 4 wire resistive touch screen:

Q: How do I install the 1.4-inch 4-wire resistive touch screen onto my device?

A: You can integrate the touch screen above an LCD or TFT panel using adhesive or a mechanical frame. Ensure proper alignment and lamination as per the installation guidelines, and connect the FPC (4-pin) to your touch controller for optimal performance.Q: What types of applications is this touch screen suitable for?

A: This touch screen is ideal for portable devices, handheld terminals, industrial equipment, kiosks, and medical devices, thanks to its durability, compact size, and responsive input capabilities.Q: When should I consider replacing the touch screen?

A: The touch screen is designed for over 1 million touches at the same spot, typically lasting about 3 to 5 years under normal usage. Replacement is recommended if you notice a decline in touch sensitivity or visible damage.Q: Where can I use this touch screen regarding environmental conditions?

A: The screen operates reliably in environments ranging from -10C to +60C and up to 90% relative humidity (non-condensing). The front panel is IP54 rated when properly mounted, making it resistant to dust and splashes-suitable for both industrial and medical settings.Q: What benefits does the anti-glare and hard-coating offer?

A: Customizable anti-glare and hard-coating treatments enhance screen visibility, reduce reflections, and improve scratch resistance, ensuring consistent performance in various lighting and handling conditions.Q: How does the resistive technology process touch input?

A: The 4-wire resistive technology detects touch by measuring changes in voltage when the ITO glass and PET film layers make contact. The analog output, processed by an external controller, accurately determines the touch point location.Q: Can this touch screen be used with different voltage supplies?

A: Yes, the touch screen supports an input voltage range of DC 3V to 5V, with a typical supply voltage of DC 5V, ensuring compatibility with various electronic systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Resistive Touch Screen Category

4 wire 5 wire resistive touch screen RS232 controller board

Price 1.0 USD ($) / Piece

Minimum Order Quantity : 10 Pieces

Size : Standard Compact

Surface Treatment : Leadfree HASL

Installation Guideline : Connect to touch screen and host device via serial RS232 interface; follow manufacturer wiring diagram

Service Period : 35 Years (Typical with Proper Usage)

7 inch 4 wire resistive touch screen

Price 1.0 USD ($) / Piece

Minimum Order Quantity : 10 Pieces

Size : 7 inch

Surface Treatment : Hard coating surface

Installation Guideline : Surface mount; adhesive or bracket (as per device design)

Service Period : Up to 1 million touch cycles

10.2 inch 4 wire resistive touch screen

Price 5.0 USD ($) / Piece

Minimum Order Quantity : 10 Pieces

Size : 10.2 Inch

Surface Treatment : Antiglare and Hard Coat Optional

Installation Guideline : Surface Mount, Align with Display, Use Adhesive or Mounting Brackets

Service Period : Typically over 1 million touches per point

15.4 Inch 5 Wire Resistive Touch Panel Screen

Price 10.0 USD ($) / Piece

Minimum Order Quantity : 10 Pieces

Size : 15 Inch

Surface Treatment : Coated

Installation Guideline : As Suggested

Service Period : 6 To 12 Months

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free