Call us now

LCD And Touch Screen Lamination, full lamination, oca lamination, touch lcd module

10.0 USD ($)/Piece

Product Details:

X

LCD And Touch Screen Lamination, full lamination, oca lamination, touch lcd module Price And Quantity

- 10 Piece

- 10.0 USD ($)/Piece

LCD And Touch Screen Lamination, full lamination, oca lamination, touch lcd module Trade Information

- SHENZHEN

- Paypal Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T)

- 10000 Piece Per Month

- 25 Days

- Yes

- Contact us for information regarding our sample policy

- Vacuum-formed tray packaging Carton Wooden

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East

- All India

- CE ROHS

Product Description

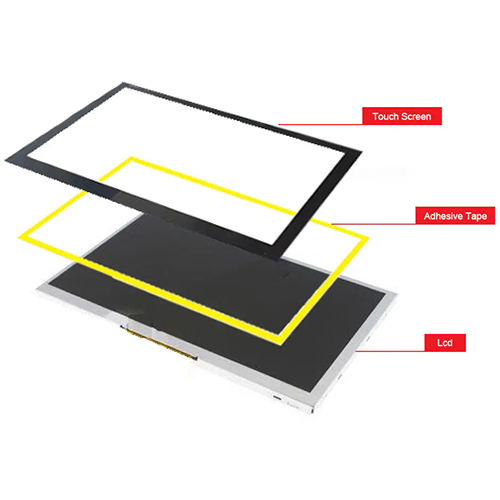

Frame/Bezel Bonding

It is a traditional method, bond the touch screen to the LCD frame by 3M adhesive tape or foam adhesive tape. There is air gap between the touch and LCD.

Suitable for the general consumer electronics, cheap cost application products, small sizes solutions.

1. Make frame bonding TOOLS

2. Bond in DUST-FREE workshop

3. Strict QUALITY control

It is a traditional method, bond the touch screen to the LCD frame by 3M adhesive tape or foam adhesive tape. There is air gap between the touch and LCD.

Suitable for the general consumer electronics, cheap cost application products, small sizes solutions.

1. Make frame bonding TOOLS

2. Bond in DUST-FREE workshop

3. Strict QUALITY control

Full Lamination ( OCA )

Process Flow

We developed a full lamination solution by FLOCA, which have advantages in the full lamination between capacitive touch screen and LCD module, especially big size LCD with metal frame , or capacitive touch screen with curved or abnormal shapes.

Surface Pretreatment Clean the surfaces of the touch screen and LCD to remove dust, oil, and impurities.

OCA Lamination (for Small to Medium-Sized Displays) Precisely attach the OCA adhesive film onto the touch screen using a vacuum laminator. Then bond the touch screen to the LCD.

Vacuum Thermal Pressing Cure the OCA adhesive completely through thermal pressing under vacuum, then degassing.

UV Curing & Quality Inspection Do UV curing and optical inspection to verify lamination quality (e.g., bubble count, alignment accuracy, and transmittance).

FLOCAFill Liquid Optical Clear Adhesive)

We developed a full lamination solution by FLOCA, which have advantages in the full lamination between capacitive touch screen and LCD module, especially big size LCD with metal frame , or capacitive touch screen with curved or abnormal shapes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry