Call us now

4.3 Inch Capacitive Touch Screen Module, kitchen touch screen

Product Details:

- Design Modern

- Size 4.3 Inch

- Surface Treatment Coated

- Installation Guideline As Suggested

- Color Different Available

- Service Period 6 To 12 Months

- Application Commercial

- Click to View more

4.3 Inch Capacitive Touch Screen Module, kitchen touch screen Price And Quantity

- 10 Piece

- 1.0 USD ($)/Piece

4.3 Inch Capacitive Touch Screen Module, kitchen touch screen Product Specifications

- Modern

- 4.3 Inch

- As Suggested

- Coated

- Different Available

- 6 To 12 Months

- Commercial

- 2 To 6 Millimeter (mm)

- Smooth

4.3 Inch Capacitive Touch Screen Module, kitchen touch screen Trade Information

- shenzhen

- Paypal Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T)

- 10000 Piece Per Month

- 25 Days

- Yes

- Contact us for information regarding our sample policy

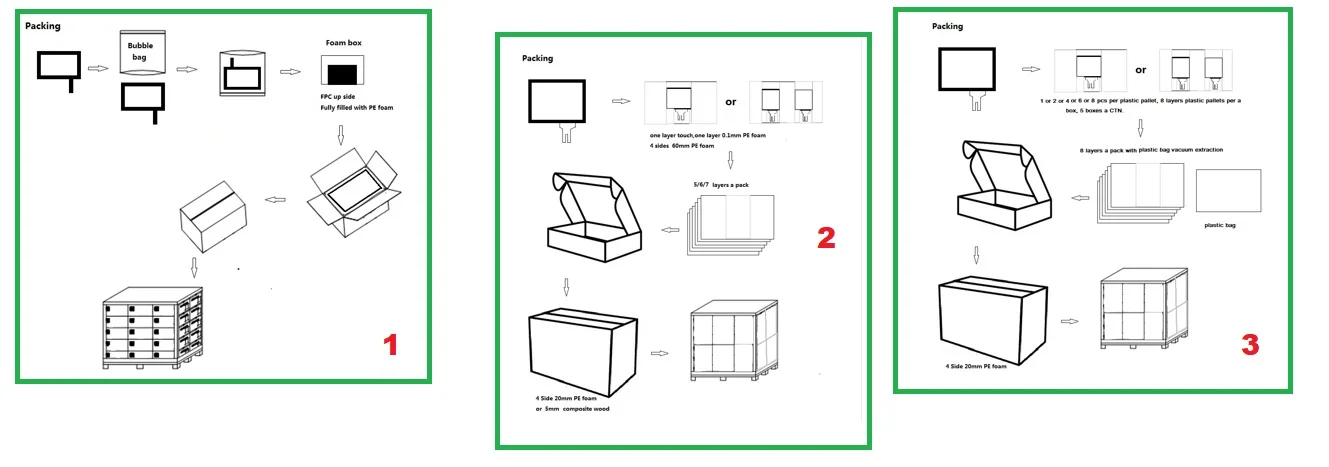

- Vacuum-formed tray packaging Carton Wooden

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East

- All India

- CE ROHS

Product Description

Products Description

4.3 inch capacitive touch panel, accept customization

Parameters:

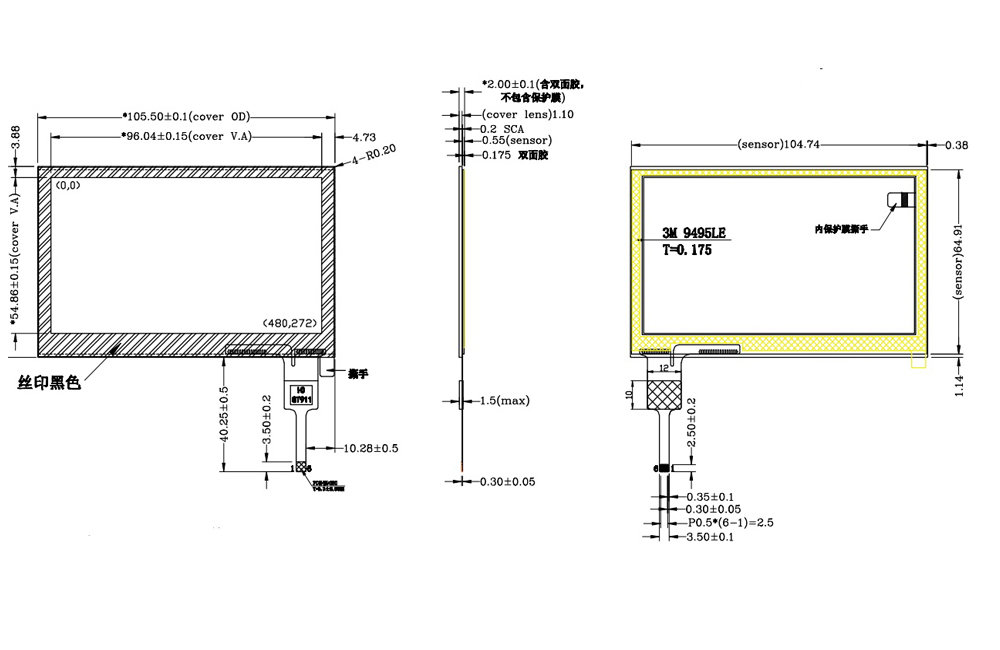

| Size | 4.3 inch Capacitive Touch Panel | |

| Outline Dimension | 105.5X67.2mm | |

| View Area | 96.04x54.86mm | |

| Active Area | 96.04x54.86mm | |

| Customization | Dimension, thikness, printings, colors etc. optional | |

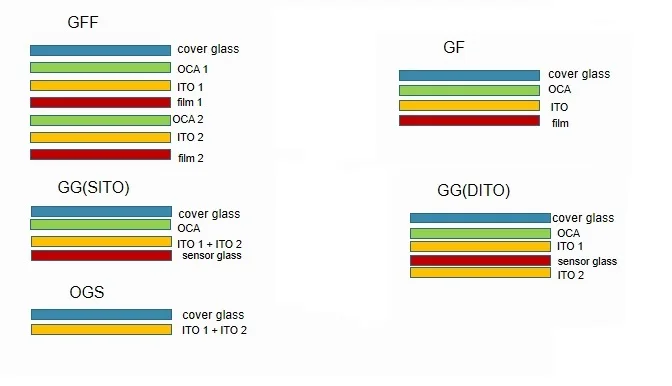

| Structure | GG/OGS/GF/GFF optional | |

| Cover glass thickness | 0.55/0.7/1.0/1.1/1.8/2.0/3.0/4.0/5.0/6.0 mm optional | |

| Glass sensor thickness | 0.4/0.55/0.7/1.1/1.8mm optional | |

| Response Speed | <5ms | |

| Input Method | Finger/Conductive Pen | |

| Touch Life | More than 50,000,000 times | |

| Resolution | 4096x4096 (Automatic match) | |

| Touch Points | 5 points | |

| Supply Voltage | 2.8-3.3V | |

| Interface | I2C | |

| Controller | Chip on FPC | |

| Surface Hardness | >6H | |

| Light Transmission | >85% | |

| Operating Temperature | -20C ~ 70C | |

| Storage Temperature | -30C ~ 80C | |

| Operation Humidity | 45-85%RH | |

| Operation System | Android, Linux, Mac, QNX etc | |

| IC solution | FocalTech,Ilitek,Goodix,Sitronix,SiS,EETI,Atmel,Cypress,HiSilicon,Handsray,Chipone etc. optional | |

| Surface treatment | AG/AR/AF etc optional | |

| Special requirements | Gloved hand/ Touch pen/mirror/Water-proof /Oil-proof/dust-proof/Woodgrain and metallic silk screen printing etc | |

Remarks:

1.GG/GF/GFF/OGS

2.Finger touch: support multiple touch and multiple gesture recognition.

3.AG: anti-glare,surface treatment

4.AR:anti-reflective,surface treatment

5.AF:anti-finger,surface treatment

6.Glove hand:mostly in Industrial or mecical application

7.Touch pen:more easy to write and draw

8.Mirror:FULL black

Cover lens

Materials:

Soda-lime glass or High-alumina glass

Thickness:

0.55mm(suggest size < 6 inch)

0.7mm(suggest size <10.1 inch)

1.0mm(custom thickness)

1.1/1.8mm( standard thickness)

2.0mm(custom thickness)

3.0mm (Standard thickness)

4.0/5.0mm(custom thickness)

Surface Treatment:

a. AF: Anti-fingerprint

Commonly used processes include spraying and electroplating. Electroplating offers better friction resistance but is more expensive.

b. AR: Anti-reflection

Using an electroplating process, it appears purple, red, or blue, giving an overall high-end visual effect.

c. AG: Anti-glare

Commonly used processes include etching and spraying. The etching process provides better friction resistance.

Glass sensor

Thickness

0.4/0.55/0.7/1.1/1.8mm

Sheet Resistance

4060 / 6090 / 80120 / 200300 : Anti-Ghosting Treatment required.

300500 / 400600 :Anti-Ghosting Treatment optional (suitable for small to medium-sized displays only).

Strengthening Treatment

Standard: No additional treatment.

Chemical Strengthening:

Recommended for: Sensors with a thickness of 0.4 mm or Structures where the sensor directly contacts the housing.

Film Sensor

Thickness

0.05mm Easily prone to pressure damage and bending damage, only suitable for small sizes)

0.075mm

0.1mm

0.125mm

Sheet Resistance

10050 : Poor etching marks, suitable for medium to large screens.

15050 : Industrially mature material, currently widely used.

OCA

Liquid OCA

Lower cost, but edge wet glue cannot be completely removed, and adhesive thickness uniformity is poor. It has been largely phased out.

Solid OCA

Higher cost, with uniform adhesive thickness, but not easy to rework during the manufacturing process. Used in some customized products long before for the unity.

UV-curable Solid OCA (SCA)

Higher cost, with uniform adhesive thickness and easy rework during the manufacturing process. Currently the mainstream material.

How to customize ? Please follow below steps:

Step 1:Tell us

a.Touch mechanical info. (touch structure,cover lens outline dimension,material,radius,printings,thickness,view area/active area,FPC position and dimension,required total touch thickness etc.)

b.Operation system,application

c.Interface,prefer IC solution

d.No.of touch points,position of origin

e.other special requirements

Step 2: According to customer's requirements or draft drawing,our RD will issue the official drawing for final checking.To do prototype production after drawing have been confirmed.Delivery date is round 2 weeks.

Step 3:Customer test the sample and feedback. Our RD department will fully support during the whole process (including remote debug and others).

Step 4:Once sample confirmed,then to start trial production.Our company will strictly do the same as samples.Not even a little change will be done before agreed by customer.Delivery date is round 3 weeks.

Suppliers:

Office:

Applications:

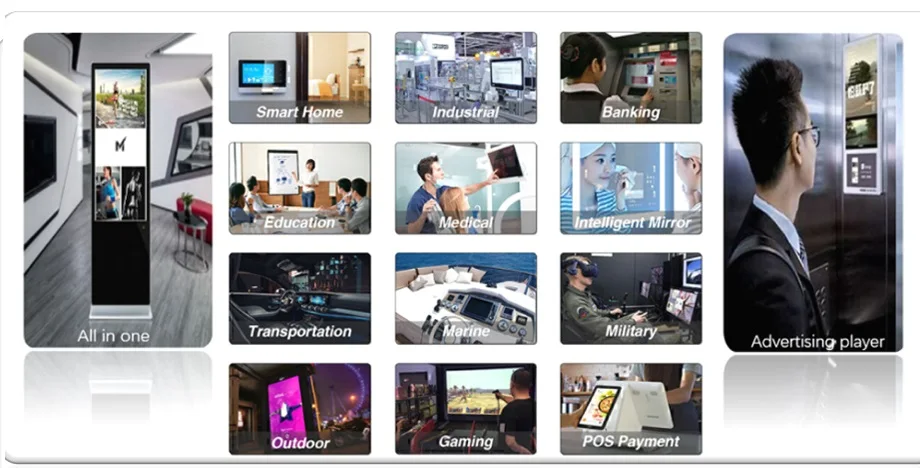

A. Consumer Electronics(Smartphones & Tablets, Smartwatches & Wearables)

B. Retail & Hospitality(POS Systems, Self-Service Kiosks)

C. Automotive(Car Infotainment Systems, Dashboard Navigation)

D. Industrial & Manufacturing(Factory Automation, Medical Devices

E. Education & Public Sector(Study tablets, E-readers, Iteractive kiosks, Advertising machine)

F. Gaming & Entertainment(Arcade Machines, Casino & Lottery Terminals, Toys)

G. Home Automation & Smart Devices(Smart Home Control Panels, Voice-Activated Touch Devices)

Packing:

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Capacitive Touch Screen' category

Send Inquiry

Send Inquiry